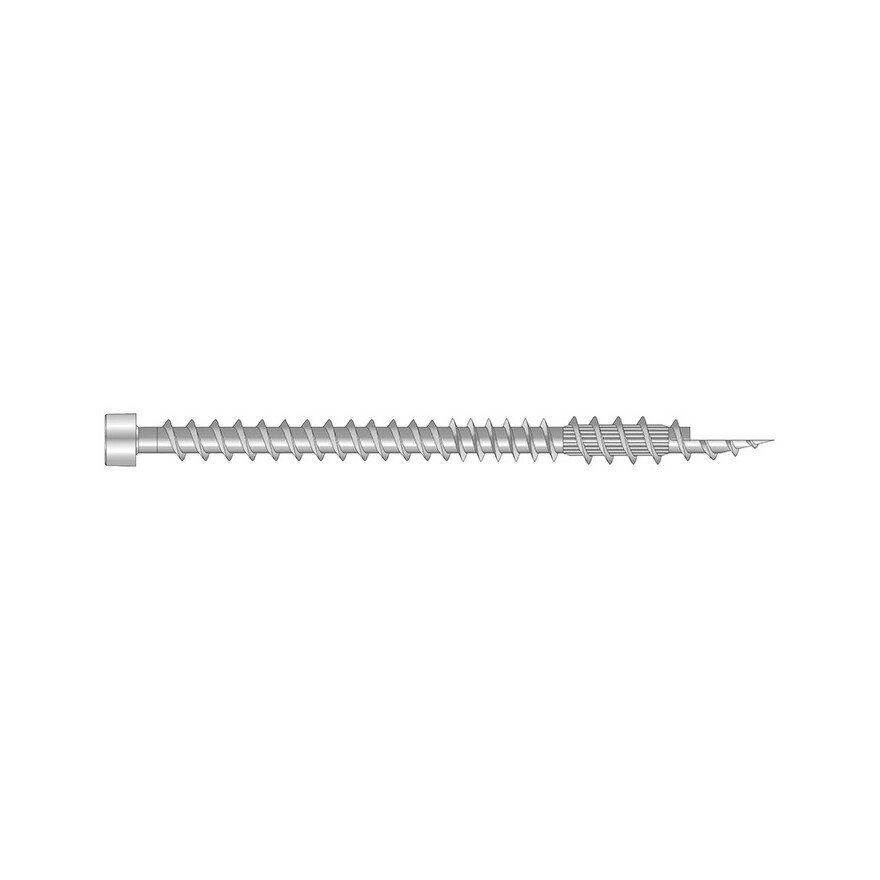

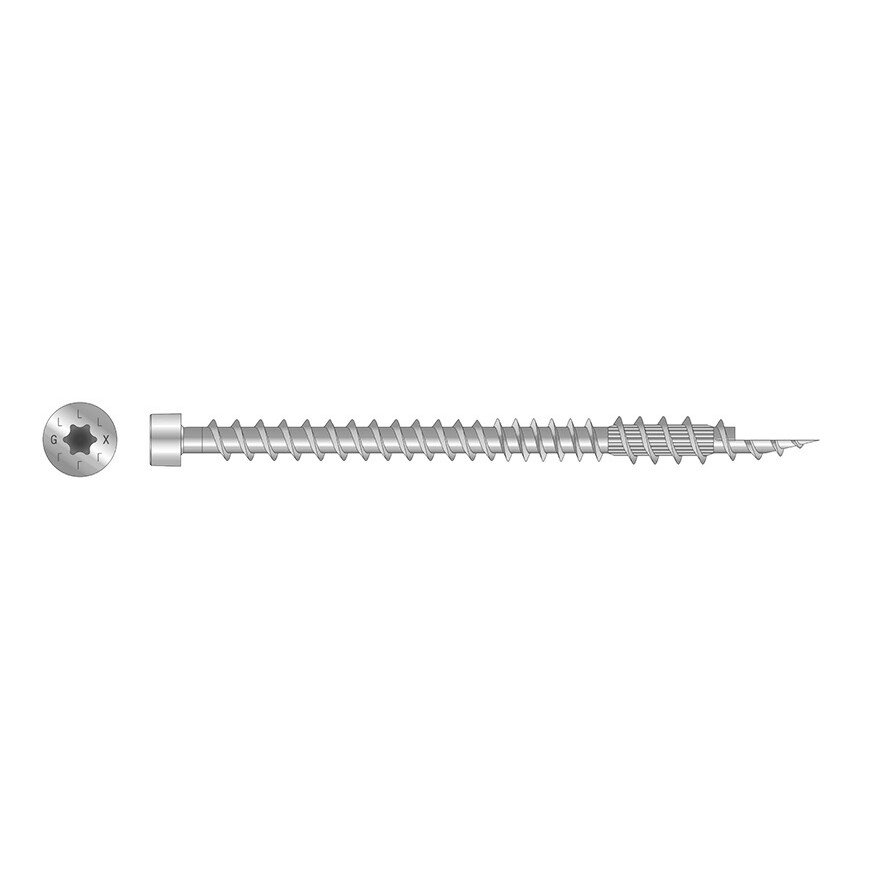

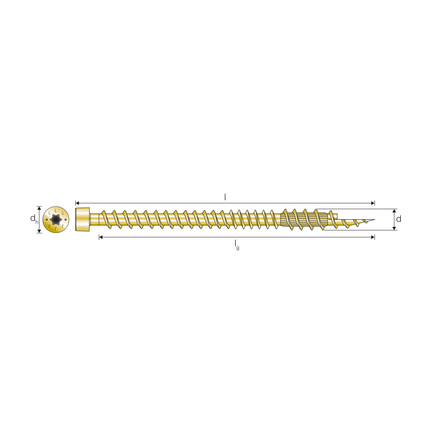

Full threaded cylinder head screw

ESCRFT is a full threaded screws with a cylinder head, suitable for hidden timber to timber assembly. It can also be used for timber reinforcement.

Produktinformasjon

Egenskaper

Material

- Hardened carbon steel

- Electrogalvanized blue passivated

Advantages

- Cylinder head: ideal for discreet timber/timber assembly with head flush with surface or sunk into timber

- Full asymetrical thread for a maximum withdrawal capacity, allows compressive load bearing

- Half cut point: reduces splitting effect and allows smaller minimum spacings and edge distances. No pre-drilling needed, easier installation when skewed

- Torx driven: reduces the wear of the bit

Applikasjoner

Suitable on

- Solid Timber, Glulam timber, CLT, Wood-based panels

When to use

- Timber to timber assembly

- Timber reinforcement (to transversile tension or compression)

- Crossed pair of screws assembly for optimal capacity

Tekniske data

Produktkarakteristiske egenskaber

| Art. nr. | Characteristic Yield Moment – My,k [Nm] | Karakteristisk uttrekks parameter - fax,k,90° [N/mm²] | Karakteristisk trekkstyrke - ftens,k [kN] | Karakteristisk hovdegjennomtrekningsparameter - fhead,k [Nm] |

|---|---|---|---|---|

| ESCRFT10 | 36.7 | 12.5 | 40 | 55 |

Montering

Montering

Spacing and Edge distances - Shear loaded screws

| Art. nr. | Minimum edge distances and spacing for shear loaded screws [mm] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Angle between load and grain = 0° | Angle between load and grain = 90° | |||||||||||

| a1.0 | a2.0 | a3.t.0 | a3.c.0 | a4.t.0 | a4.c.0 | a1.90 | a2.90 | a3.t.90 | a3.c.90 | a4.t.90 | a4.c.90 | |

| ESCRFT10 | 50 | 40 | 80 | 40 | 30 | 30 | 40 | 40 | 80 | 70 | 40 | 30 |

a1 and a2 can be multiplied by 0.85 for panel/timber assembly, and by 0.7 for steel/timber assembly.

Spacing and edge distances - Axially loaded screws

| Art. nr. | Minimum edge distances and spacing for axially loaded screws [mm] | |||

|---|---|---|---|---|

| a1 | a2 | a3.c | a4.c | |

| ESCRFT10 | 50 | 50 | 50 | 40 |

Abacus

Timber to Timber characteristic capacities

| Art. nr. | Product characteristic capacities - Timber to Timber C24 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Axial resistance | Shear resistance parallel to the grain depending of t1 [Rv.0.k] [kN] | Shear resistance perpendicular to the grain depending of t1 [Rv.90.k] [kN] | ||||||||||||||

| t1 [mm] | Rax.k [kN] | 35 [mm] | 40 [mm] | 45 [mm] | 60 [mm] | 75 [mm] | 80 [mm] | ≥100 [mm] | 35 [mm] | 40 [mm] | 45 [mm] | 60 [mm] | 75 [mm] | 80 [mm] | ≥100 [mm] | |

| ESCRFT10.0X450 | 225 | 24.25 | - | 9.1 | 9.77 | 10.01 | 10.01 | 10.01 | 10.01 | - | 6.59 | 7.02 | 8.18 | 8.18 | 8.18 | 8.18 |

| ESCRFT10.0X500 | 250 | 27.38 | - | 9.1 | 9.77 | 10.01 | 10.01 | 10.01 | 10.01 | - | 6.59 | 7.02 | 8.18 | 8.18 | 8.18 | 8.18 |

| ESCRFT10.0X600 | 300 | 33.63 | - | 9.1 | 9.77 | 10.01 | 10.01 | 10.01 | 10.01 | - | 6.59 | 7.02 | 8.18 | 8.18 | 8.18 | 8.18 |

| ESCRFT10.0X800 | 400 | 40 | - | 9.1 | 9.77 | 10.01 | 10.01 | 10.01 | 10.01 | - | 6.59 | 7.02 | 8.18 | 8.18 | 8.18 | 8.18 |

| ESCRFT10.0X1000 | 500 | 40 | - | 9.1 | 9.77 | 10.01 | 10.01 | 10.01 | 10.01 | - | 6.59 | 7.02 | 8.18 | 8.18 | 8.18 | 8.18 |

These capacities are valid for:

- Timber element under the head with thickness ≤ t1 disclosed in adjacent column

- Screw axis between 45° and 90° from timber grain for ESCR(XXX), and 90° from timber grain for all other screws.

For tightening screws (partially threaded), t1 dimension is the maximum thickness of the under-head timber member for which the thread is fully in the pointside timber member, for an optimum installation and tightening.

The shear capacities are given for several timber thicknesses t1 of the under-head member under the following configurations:

- Load axis at 0° from both timber grains Rv.0°.k

- Load axis at 90° from both timber grains Rv.90°.k

These capacities are valid for C24 timber grades or higher

The pre-drilled hypothesis for capacity and distances calculation is fulfilled.

For partial threaded screws, capacities are only given for configurations where the thread is less than 5mm in under-head timber member, in order to achieve optimum installation and tightening.

Clause (2) in 8.3.1.2 from EN1995-1-1:2004+A2:2014 about embedment length is ignored in these calculations.

Timber to Timber - Cross pair of screws

| Art. nr. | Crossed pair of screws - characteristic capacities | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Header | Joist | Installation distance | Characteristic capacities (Pull-out / Buckling) Rv.pair = min(Rw.k.pair ; Rbuck.k.pair) [kN] | |||||||

| hj min [mm] | 1 pair | 2 pairs | m [mm] | mi [mm] | 1 pair | 2 pairs | ||||

| bj min [mm] | bj min 2 [mm] | Rw.k.pair [kN] | Rbuck.k.pair [kN] | Rw.k.pair [kN] | Rbuck.k.pair [kN] | |||||

| ESCRFT10.0X450 | 170 | 331 | 105 | 155 | 164 | 169 | 34.29 | 17.14 + 19.62 /kmod | 64 | 31.99 + 36.62 /kmod |

| ESCRFT10.0X500 | 187 | 366 | 105 | 155 | 181 | 186 | 38.71 | 19.35 + 19.62 /kmod | 72.2 | 36.12 + 36.62 /kmod |

| ESCRFT10.0X600 | 223 | 437 | 105 | 155 | 217 | 222 | 47.55 | 23.77 + 19.62 /kmod | 88.7 | 44.36 + 36.62 /kmod |

| ESCRFT10.0X800 | 293 | 578 | 105 | 155 | 287 | 292 | 56.57 | 28.28 + 19.62 /kmod | 105.6 | 52.78 + 36.62 /kmod |

| ESCRFT10.0X1000 | 364 | 719 | 105 | 155 | 358 | 363 | 56.57 | 28.28 + 19.62 /kmod | 105.6 | 52.78 + 36.62 /kmod |